The Advantages of Making Use Of Industrial Scales for Precision and Performance

In today's competitive landscape, the application of commercial ranges has become a crucial approach for enhancing precision and functional effectiveness. These tools not just make certain accurate measurements, which are necessary for quality assurance and compliance, but likewise improve different procedures that decrease waste and reduce costs. Their versatility throughout diverse industries such as manufacturing, logistics, and agriculture further highlights their relevance. Nevertheless, the broader effects of taking on industrial scales extend past mere accuracy-- what transformative influences can they generate for organizations intending to maximize their procedures?

Improved Precision in Measurements

Regularly utilized in numerous industrial applications, commercial ranges use enhanced precision in dimensions that is crucial for maintaining operational effectiveness. These scales are created to give specific weight readings, which are necessary for markets such as production, logistics, and food processing. Precise measurements contribute significantly to item quality, guaranteeing that materials are weighed properly and constantly, therefore minimizing waste and reducing prices.

In enhancement, the capacity to acquire exact dimensions permits far better supply administration (Industrial Scales). By properly tracking the weight of resources and finished products, companies can enhance their supply chain processes, causing improved planning and forecasting. This level of precision additionally sustains conformity with sector regulations, as many fields call for strict adherence to weight criteria for safety and security and quality control

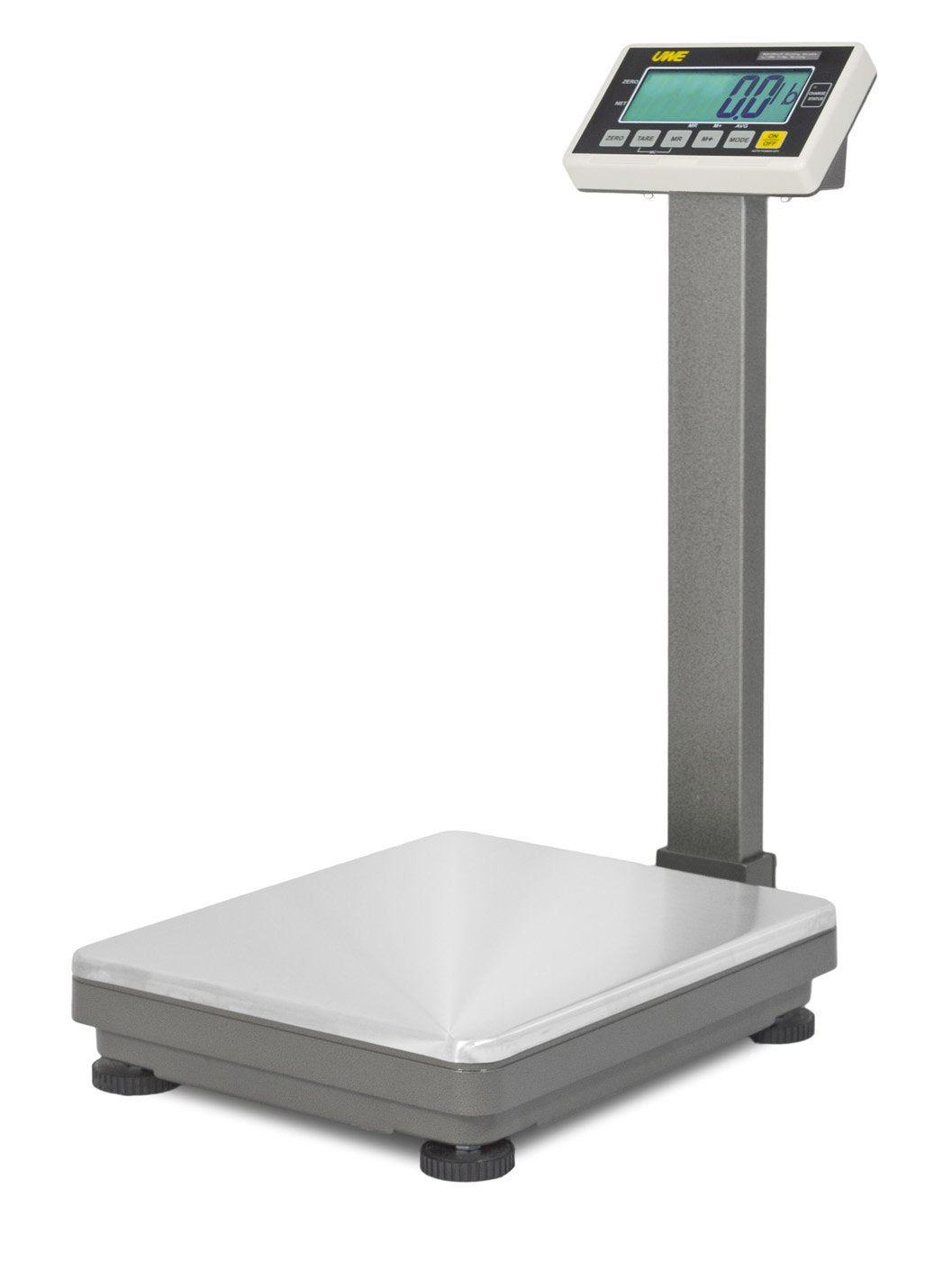

Furthermore, progressed industrial scales frequently come outfitted with features such as electronic display screens and connection options, assisting in real-time information collection and evaluation. This integration enhances decision-making processes by supplying stakeholders with reliable info at their fingertips. On the whole, the boosted accuracy of industrial scales is a fundamental element that straight influences efficiency and functional honesty across various fields.

Boosted Functional Efficiency

Among the most considerable advantages of commercial scales is their role in boosting functional effectiveness across various markets. By supplying quick and precise weight measurements, these ranges streamline processes that count heavily on specific data. In production, for example, timely measurement of raw materials makes sure that production schedules remain nonstop, dramatically decreasing downtime.

Moreover, industrial ranges facilitate much better supply monitoring. Precise weight readings make it possible for firms to preserve optimal supply levels, avoiding overstocking or stockouts, which can prevent operations. In logistics, specific considering is critical for optimizing lots ability and making sure compliance with transportation guidelines, therefore enhancing the overall circulation of items.

Additionally, the integration of industrial scales with automated systems can result in smooth information transfer and analysis, enabling for real-time surveillance and modifications in assembly line. This connectivity not only promotes agility in operations however likewise supports educated decision-making based upon precise information.

Price Decrease and Waste Minimization

Lessening and minimizing costs waste are important goals for services in any type of sector, and commercial ranges play an essential role in achieving these goals. By ensuring exact dimensions, commercial ranges aid organizations maximize their material usage, which directly contributes to cost decrease. Unreliable considering can bring about over-ordering or under-utilization of resources, leading to unneeded expenditures.

Additionally, industrial ranges make it possible for companies to keep an eye on inventory levels precisely, permitting far better demand forecasting and inventory management. This capability decreases the danger of excess supply that may go to throw away, particularly in sectors taking care of subject to spoiling products.

The integration of industrial ranges can also improve manufacturing procedures. Industrial Scales. By gauging basic materials properly, services can reduce wasting and remodel, additionally reducing operational costs

Quality Assurance and Compliance

Precise dimension is not only vital for price decrease and waste minimization but also plays a significant function in preserving high quality control and ensuring compliance with industry standards. In industrial settings, exact weight dimensions are essential for confirming that products fulfill requirements and governing needs. Utilizing industrial scales enhances the dependability of dimensions, which is important for regular item top quality.

In addition, exact dimensions assist in official source determining variances from developed requirements early in the production process. This proactive method reduces the risk of non-compliance with governing bodies, which can bring about expensive charges and damage to brand reputation. Industries such as food and pharmaceuticals, where security and quality are paramount, heavily rely upon accuracy ranges to ensure that ingredients and final items stick to strict guidelines.

Furthermore, routine calibration and maintenance of industrial scales are needed to keep their accuracy, more strengthening quality control procedures. By executing industrial scales into their procedures, companies not just improve their processes but likewise strengthen their dedication to high quality and conformity, cultivating trust fund amongst consumers and stakeholders alike. Ultimately, the combination of exact dimension tools fortifies the structure for operational quality.

Convenience Across Industries

Industrial like it ranges demonstrate exceptional versatility, adapting to the unique needs of different industries consisting of production, logistics, and farming. In production, these scales are essential for quality control, ensuring products fulfill requirements by properly measuring final outputs and raw products. This precision straight influences production efficiency and reduces waste.

In farming, commercial scales help in the exact dimension of fruit and vegetables, assisting farmers in monitoring returns and taking care of sources properly. They are important for figuring out prices based on weight, therefore affecting revenue margins dramatically.

Moreover, the adaptability of industrial ranges reaches the food handling and pharmaceuticals sectors, where stringent guidelines demand accurate measurements for security and efficacy. By offering diverse applications throughout multiple fields, industrial scales stay crucial tools that enhance both precision and efficiency in operations. Their convenience guarantees they satisfy the specific needs of each sector, driving efficiency and conformity.

Verdict

Finally, the utilization of commercial ranges dramatically adds to improved precision and functional effectiveness across various industries. These scales not just help with cost reduction and waste reduction yet additionally play an important duty in maintaining quality control and making certain conformity with industry laws. Their flexibility permits tailored applications in varied fields, eventually cultivating a culture of accuracy and informed decision-making that improves find out this here total performance and resource use within organizations.

Frequently used in various commercial applications, industrial ranges provide boosted accuracy in measurements that is critical for keeping functional performance. By making certain specific dimensions, industrial scales assist companies enhance their material use, which straight contributes to set you back reduction. Industrial Scales. Utilizing industrial scales improves the integrity of dimensions, which is vital for consistent item quality

In addition, the flexibility of commercial ranges expands to the food processing and drugs markets, where rigid policies necessitate exact measurements for safety and effectiveness.In conclusion, the use of industrial ranges substantially contributes to improved accuracy and operational performance across various fields.

Comments on “Why Accuracy Matters When Picking Industrial Scales for Work”